In the era of modern industry, the demand for new, efficient, and versatile materials is growing rapidly. One of the most outstanding solutions to meet this demand is engineering plastics of Green Roofing. With the ability to withstand harsh working conditions and flexible applications across various industries, engineering plastics have become a widely used material in industrial manufacturing.

Renowned for their exceptional properties such as high mechanical strength, heat resistance, chemical resistance, and ease of processing, engineering plastics continue to contribute to the development of high-value products across multiple sectors.

Engineering Plastics – A Versatile Material with Superior Performance

Engineering plastics are manufactured from high-grade engineering polymers, offering exceptional stability, making them particularly suitable for applications requiring high precision and load-bearing capacity in harsh environments. These strengths have made engineering plastics a preferred choice in many industrial manufacturing sectors.

Key Advantages of Engineering Plastics

-

High Mechanical Strength: Engineering plastics exhibit excellent load-bearing capacity and rigidity, providing resistance to wear, impact, and deformation under external forces. Thanks to these properties, they are widely used in components requiring high strength, such as automotive parts, industrial machinery, and electronic devices.

-

Superior Wear and Friction Resistance: With outstanding wear resistance, engineering plastics help extend the lifespan of products used in continuous operation, minimizing the need for frequent replacements or maintenance.

-

Heat Resistance and Electrical Insulation: Engineering plastics can perform efficiently in high-temperature environments, with some variants capable of withstanding temperatures up to 200°C without deformation. Additionally, they possess excellent electrical insulation properties, making them ideal for applications in electronics, telecommunications, and electrical equipment.

-

Chemical Resistance: Engineering plastics can withstand a wide range of chemicals, including acids, solvents, and cleaning agents. Some materials, such as PTFE (Teflon), are resistant to almost all chemicals, making them ideal for use in the chemical, pharmaceutical, and food industries.

-

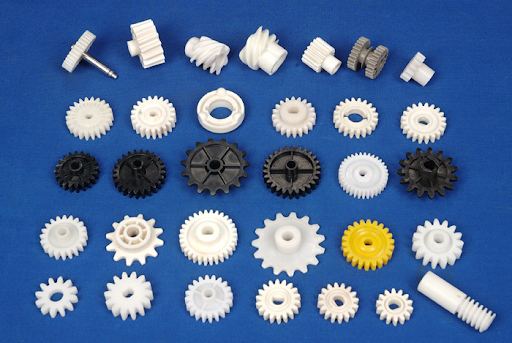

Easy Machining and Molding: One of the standout advantages of engineering plastics is their ease of processing and shaping. They can be manufactured into intricate components with complex geometries, small diameters, or thin structures, catering to diverse industrial needs. Engineering plastics can be processed using various methods, including injection molding, casting, cutting, and CNC machining.

Applications of Engineering Plastics in Various Industries

Wide-Ranging Applications of Engineering Plastics

Engineering plastics are now extensively utilized across numerous industries, from automotive and electronics to medical devices and food packaging. Below are some of the most notable applications:

-

Automotive Industry: Engineering plastics are a primary material in manufacturing automotive components such as vehicle exteriors, dashboards, mechanical parts, and other accessories. Thanks to their durability, lightweight nature, and ease of processing, these materials help reduce vehicle weight, improve fuel efficiency, and enhance safety. Additionally, engineering plastics contribute to cost reduction while increasing the quality and longevity of automotive components.

-

Electronics and Telecommunications: In the electronics sector, engineering plastics are used to produce device casings, electronic components, circuit boards, connectors, and parts that must withstand heat and electrical exposure. With their excellent insulating properties and heat resistance, engineering plastics ensure the safety of electronic devices while extending product lifespan.

-

Medical Industry: Engineering plastics play a crucial role in the production of medical devices, surgical instruments, medical filters, and other healthcare products. Materials like Polycarbonate (PC), Polyethylene (PE), and PEEK are commonly used due to their antibacterial properties, ease of sterilization, and chemical resistance. These plastics help create safe, high-precision products for medical applications.

-

Food Packaging Industry: Engineering plastics are widely used in the packaging sector due to their barrier properties, chemical resistance, and recyclability. Materials such as PET, PP, PVC, and HDPE are commonly employed in food packaging, protecting products from external factors and extending shelf life. Additionally, engineering plastics enhance the visual appeal and transport efficiency of packaged goods.

Sustainability and Future Trends

Sustainability and Future Trends

One of the key factors driving the growing popularity of engineering plastics is their sustainability. The use of these materials helps reduce reliance on heavy metals, while their recyclability minimizes environmental impact. Additionally, engineering plastics serve as viable alternatives to traditional materials, contributing to energy savings and cost efficiency throughout their lifecycle.

With continuous advancements in technology, engineering plastics are becoming more refined and diverse. Ongoing research and innovation in this field not only enhance the performance of these materials but also focus on reducing their environmental footprint, aligning with the global trend toward sustainable industrial development.

Green Roofing – Your Trusted Partner for Polycarbonate Solutions

Green Roofing is more than just a supplier of polycarbonate sheets; we are a comprehensive partner dedicated to turning your construction ideas into reality. With high-quality products that meet industry standards, extensive experience, and a commitment to exceptional service, Green Roofing Co., Ltd. is the ideal choice for contractors and customers alike.

Committed to developing eco-friendly and sustainable structures, Green Roofing strives to create modern and durable living and working environments. If you're looking for a comprehensive and efficient solution for your project, contact Green Roofing today for the best support!

GREEN ROOFING Co., ltd

Hotline: 0932 06 6699 - (028) 6681 7799

Email: info@greenroofing.vn

Website: https://www.greenroofing.vn/