CNC Machining is a modern method that utilizes computer control to operate CNC milling and CNC turning techniques, enabling high-precision cutting and shaping of polycarbonate sheets. This method is ideal for manufacturing complex components and is widely applied in industries such as manufacturing, construction, healthcare, advertising, and the automotive sector, delivering exceptional efficiency.

Definition

CNC machining (Computer Numerical Control) is a mechanical processing method that utilizes computer-controlled machinery to cut, shape, or engrave various materials such as metals, plastics, and especially polycarbonate sheets. This method is distinguished by its high precision, fast processing speed, and consistent repeatability, enabling the production of complex components with minimal tolerance deviations.

The CNC machining process for polycarbonate includes turning, milling, and drilling techniques. While polycarbonate is not difficult to cut, using sharp tools and appropriate equipment is recommended to minimize vibrations and ensure safety.

During CNC machining, polycarbonate is cut or shaped based on CAD (Computer-Aided Design) models using G-Code commands. This method is ideal for manufacturing high-precision components, from prototyping to small- and medium-scale production. Once the CNC system is activated, the desired cutting paths are programmed into the software and transmitted to the respective tools and machines, which then execute the dimensional tasks as instructed—much like a robot.

In CNC programming, the system's code generator assumes that the mechanisms are flawless, although errors can occur—especially when the CNC machine is instructed to cut in multiple directions simultaneously. The position of a tool in the numerical control system is outlined by a series of inputs known as a part program.

Two Widely Applied CNC Machining Methods: Milling and Turning

CNC Milling

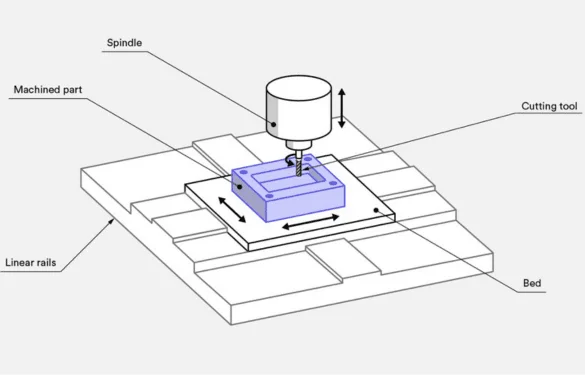

CNC milling is a machining process that utilizes computer control to manage the movement and operation of multi-point rotating cutting tools. As these tools spin and traverse the surface of the workpiece, they gradually remove excess material to achieve the desired shape and dimensions.

The CNC Milling Process

The CNC milling process can be divided into four distinct stages:

- CAD Model Design: Engineers create a 2D or 3D design of the desired component.

- Conversion of CAD Model to CNC Program: The design is exported to a compatible file format and converted into machine instructions using CAD software.

- CNC Milling Machine Setup: The operator prepares the machine and secures the workpiece.

- Milling Operation Execution: The operator initiates the machining program, and the CNC system processes the workpiece accordingly.

The CNC milling process begins with converting the CAD model into G-code commands, enabling the CNC machine to interpret and execute the machining process according to the design. Operators typically perform this step based on the provided technical drawings. Next, the workpiece is cut to the required dimensions and securely fixed onto the machine table using jigs or direct clamps. To ensure high precision, the workpiece is carefully aligned using measuring tools such as touch probes. The CNC machine then performs rough machining, using high-speed rotating cutting tools to quickly remove excess material and shape the workpiece close to the final design. Subsequently, finishing tool paths are applied for fine machining, achieving the desired accuracy and surface quality. If the part has hard-to-reach areas that cannot be machined in a single setup, the workpiece is reoriented or rotated to complete the remaining sections. This process ensures that the final product meets technical standards with high precision and a superior surface finish.

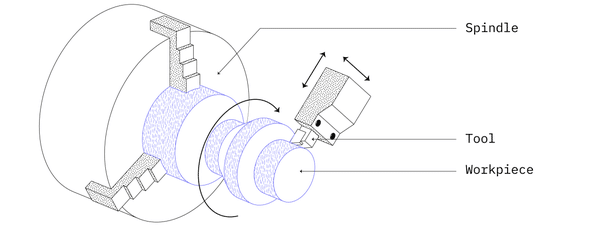

CNC Turning (Computer Numerical Control Turning) is a precision machining method in which the workpiece is mounted on a rotating chuck, and material is removed using stationary cutting tools. This process is primarily used to create symmetrical parts along the central axis, ensuring high precision and superior manufacturing efficiency.

Compared to CNC milling, CNC turning is generally faster and more cost-effective for machining cylindrical components.

Basic CNC Turning Process

Generating G-Code from CAD Design: The design is converted into G-code and uploaded to the CNC machine to control machining steps.

Workpiece Preparation: A cylindrical workpiece with the appropriate diameter is placed into the machine’s chuck and securely clamped.

Machining

The workpiece rotates at high speed while a stationary cutting tool moves along the pre-programmed turning profile, gradually removing material until the part reaches the desired shape.

If drilling along the central axis is required, a center drill or internal cutting tool is used.

Finishing the Part: If repositioning or flipping the workpiece is necessary, the process is repeated. Once completed, the finished part is cut from the workpiece and is ready for further processing.

Advantages and Disadvantages

Advantages of CNC Machining Polycarbonate

- High Precision: CNC machining produces parts with tight tolerances, ensuring accurate dimensions and shapes.

- Versatile Designs: Capable of machining complex parts, from simple geometric shapes to intricate structures.

- Material Integrity: Polycarbonate retains its mechanical properties after machining, such as impact resistance and strength.

- Efficient Production: Suitable for small to medium batch production, reducing material waste.

Common Challenges in CNC Machining Polycarbonate

- Prone to Scratches: Polycarbonate surfaces must be handled carefully to prevent damage during machining and finishing.

- Thermal Deformation: Heat generated during cutting can soften or deform the material if not properly managed.

- Higher Costs: Cutting tools wear out quickly due to polycarbonate's abrasive nature, increasing tool replacement expenses.

- Difficulties in Large-Scale Machining: Large polycarbonate sheets can warp or deform during clamping and machining.

📞 Contact us today for a detailed quote and expert consultation!

GREEN ROOFING CO., LTD.